Industrial Fan Heaters Installed at Shelley Thermoformers International in Huntingdon, Cambridgeshire Cambridgeshire

Project Type

Warehouse/Factory Heating

The Project

The management at Shelley Thermoformers International invited a BN Thermic engineer to their Huntingdon facility to discuss the heating options for their workshop. Although the workshop is relatively large, the workbenches are located along one wall meaning that two different heating approaches could be considered.

Two Possible Heating Technologies

One possibility was to spot heat the workbenches directly without making any attempt to heat the main body of the workshop.

The second option was to provide conventional space heating by means of an industrial fan heater.

Spot Heating with Quartz Halogen Heaters

Spot heating is often the preferred option when workstations occupy a relatively small percentage of a building’s total area. It is an even more attractive option when the workstations themselves are used intermittently.

The concept is simple. Rather than heat an entire building, we can use the unique heating characteristics of quartz halogen heaters to provide direct heat to individual workstations which only need to be heated when they are occupied.

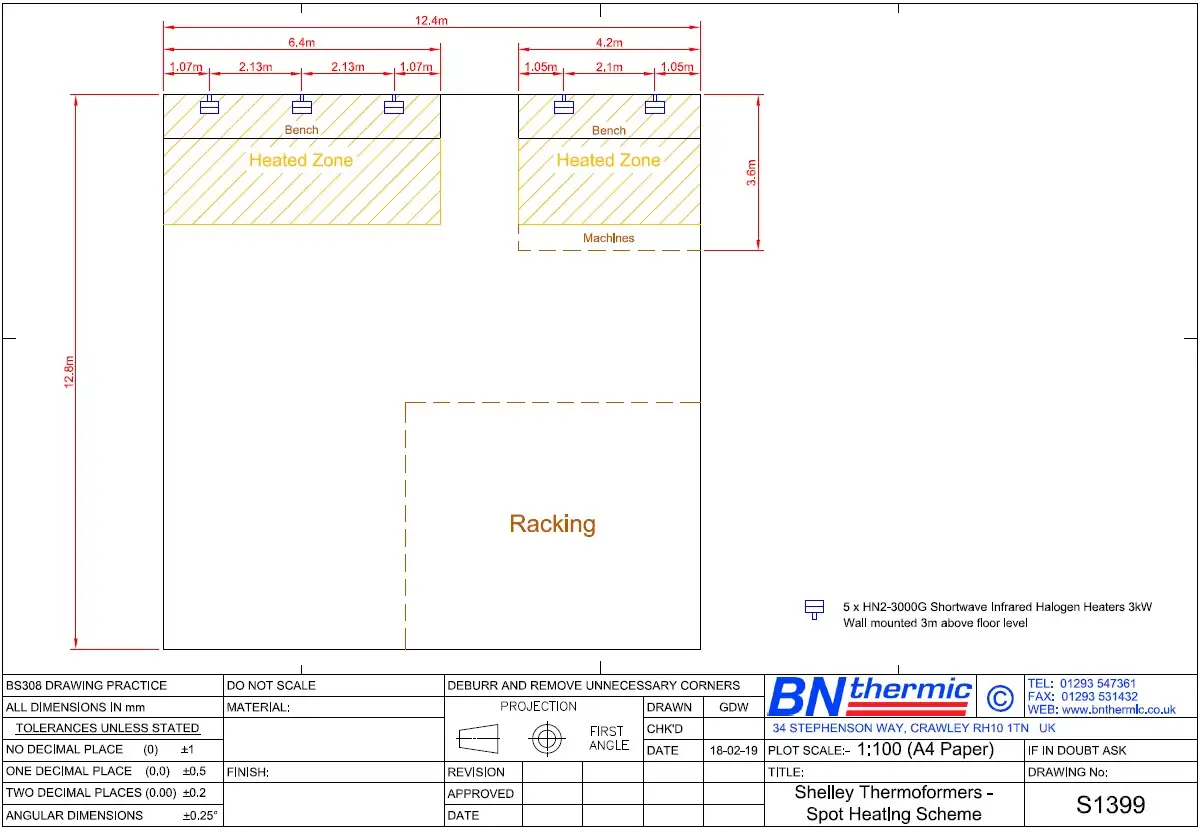

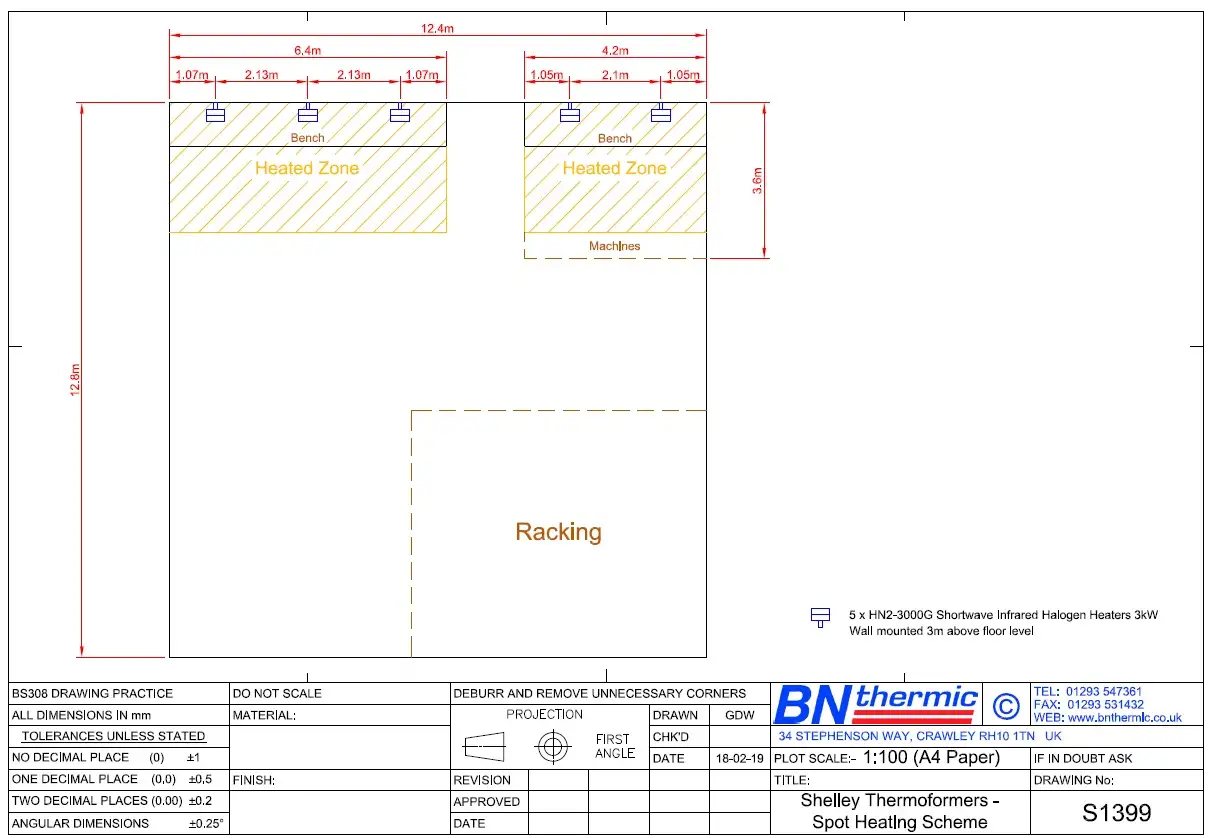

The design using quartz halogen heaters

Quartz heaters provide instant comfort heat making them ideal for intermittently used areas

Quartz Halogen Heaters

For this project, BN Thermic recommended a total of five 3kW quartz halogen heaters with each one controlled by a push-button time delay switch. The timer can be preset at between two minutes and two hours and as soon as the preset time period has elapsed, the heaters will be switched off automatically.

In large buildings with a relatively small number of intermittently used workstations, a spot heating approach can reduce heating bills dramatically.

Space Heating with an Industrial Fan Heater

An industrial fan heater provides heating in a more conventional sense. The key to a successful installation is to ensure that the heater has sufficient kW output to offset heat losses during the depth of winter and that the required thermostatic control is provided to keep running costs to a minimum.

The design using industrial fan heaters

BN Thermic manufacture industrial fan heaters from 3kW right up to 25kW

Industrial Fan Heaters

For Shelley Thermoformers’ workshop, a 25kW industrial fan heater was specified with an integral adjustable thermostat for temperature control and a remote mounted programmable timer.

To further improve economy, a destratification unit was also recommended. This device is suspended from the roof and automatically recycles super-heated air that accumulates at high level. The use of destratification unit can reduce heating costs by up to 30%.

The Decision

BN Thermic provided a detailed proposal for both heating options. The final decision was to use the industrial fan heater to provide conventional space heating together with a destratification unit for enhanced economy.

BN Thermic industrial fan heaters have a built in thermostat as standard

The main reason for this decision was that the space heating option also provided some background heat for the items stored in the workshop which would not be the case with the spot heating option.

We hope that this case study shows the extent to which BN Thermic will engage with its customers to ensure that the optimum heating system is installed.

If you would like a BN Thermic engineer to assist with your heating project, please call us on 01293 547361.

Related Case Studies

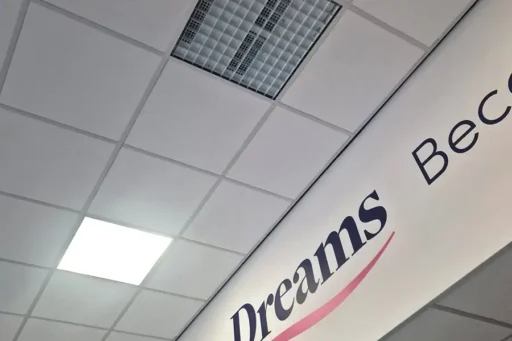

Ceiling Grid Heaters Installed at Dreams Beds

Project Type: Shop Heating

Location: Horsham, West Sussex

Longwave Radiant Cassettes Installed in a Modern Showroom in Bedfordshire

Project Type: Shop Heating, Warehouse/Factory Heating

Location: Bedfordshire